We carry sizes from 3″ x 3″ to 60″ x 60″ including new sling bags with double-reinforced bottoms for mops. Perfect for healthcare and hazardous waste facilities, avoid contamination and prevent infections with our environmentally friendly and hygienic solution to minimize contact between staff and infected laundry. Isolate, store, transport and clean soiled clothing, uniforms, bed linens, etc. without fear of airborne bacteria, infectious body fluids or blood-borne pathogens – our bags dissolve completely and are highly resistant to most organic solvents, greases, fats and oils, are impervious to most gases and will not generate a static charge.

For Wet or Dry Applications, we have extra-heavy duty PLUS 2 bags for wet and dry mops, towels and garments; standard and heavy duty bags for dry soiled or contaminated linens, towels and garments; biohazard bags; and special bags for dry welding garments (that comply with OSHA’s regulations for hexavalent chromium handling) – these cost-effective, puncture resistant bags allow for several days of wet or dry storage without items rupturing the bottoms of the bags. All our bags are latex free and will not damage fabrics, equipment or waste water treatment systems! Most sizes use an attached tie-tape to close.

Used By:

- Healthcare and Hazardous Waste Facilities

- Commercial Laundries

- Hospitals

- Prisons

- Nursing Homes

- Hotels

We Also Have Bags For:

- Cement Pigmenters

- Bed Bug Exterminators

- Mixing Dyes for fabrics in textile industry

Our bags meet or exceed the stringent guidelines and regulations of:

- U.S. CENTERS FOR DISEASE CONTROL AND PREVENTION (CDC)

- U.S. OCCUPATIONAL SAFETY AND HEALTH ADMINISTRATION (OSHA)

- HEALTHCARE LAUNDRY ACCREDITATION COUNCIL (HLAC)

- EUROPEAN STANDARD EN 14065:2002 TEXTILES – LAUNDRY PROCESSED

- TEXTILES – BIO-CONTAMINATION CONTROL SYSTEM

- NHS HOSPITAL LAUNDRY ARRANGEMENTS FOR USED AND INFECTED LINEN, U.K. HSG (95)18

- NATIONAL FIRE PROTECTION ASSOCIATION 56A “STANDARD FOR THE USE OF INHALATION ANESTHETICS.”

Specialty Bags for Sling Mops

Water Soluble Bags Stock Sizes

Standard Duty Cold Water Soluble Bags

Dissolves in water above 25°C or 77°F

| P/N | Size | Description | Qty/Case |

| 1519220 | 19″ x 22″ x .8 mil |

| 100 |

| 1526330 | 26″ x 33″ x .8 mil |

| 100 |

| 1528390 | 28″ x 39″ x .8 mil |

| 100 |

Heavy Duty Cold Water Soluble Bags

Dissolves in water above 25°C or 77°F

| P/N | Size | Description | Qty/Case |

| 1626330 514 | 26″ x 33″ x 1 mil |

| 100 |

| 1628390 516 | 28″ x 39″ x 1 mil |

| 100 |

| 1636390 518 | 36″ x 39″ x 1 mil |

| 100 |

Standard Duty Hot Water Soluble Bags

Dissolves in water above 65°C or 149°F

| P/N | Size | Description | Qty/Case |

| 1119220 | 19″ x 22″ x .8 mil |

| 100 |

| 1126330 500 | 26″ x 33″ x .8 mil |

| 100 |

| 1126331 501 | 26″ x 33″ x .8 mil |

| 100 |

| 1126334 | 26″ x 33″ x .8 mil |

| 100 |

| 1128390 502 | 28″ x 39″ x .8 mil |

| 100 |

| 1128391 | 28″ x 39″ x .8 mil |

| 100 |

| 1128394 | 28″ x 39″ x .8 mil |

| 100 |

| 503 | 28″ x 39″ x .8 mil |

| 100 |

| 1136390 504 | 36″ x 39″ x .8 mil |

| 100 |

| 1136393 | 36″ x 39″ x .8 mil |

| 100 |

| 505 | 36″ x 39″ x .8 mil |

| 100 |

| 1136394 | 36″ x 39″ x .8 mil |

| 100 |

| IH019 | 36 x 39″ x .8 mil |

| 100 |

Heavy Duty Hot Water Soluble Bags

Dissolves in water above 65°C or 149°F

| P/N | Size | Description | Qty/Case |

| 1112302G CLOSEOUT | 12″ x 30″ x 1 mil |

| 100 |

| 1219220 506 | 19″ x 22″ x 1 mil |

| 100 |

| 1226330 508 | 26″ x 33″ x 1 mil |

| 100 |

| 1228390 510 | 28″ x 39″ x 1 mil |

| 100 |

| 1228390G CLOSEOUT | 28″ x 39″ x 1 mil |

| 100 |

| 1228391 | 28″ x 39″ x 1 mil |

| 100 |

| 1228394 IH015 | 28″ x 39″ x 1 mil |

| 100 |

| 1236390 512 | 36″ x 39″ x 1 mil |

| 100 |

| 1236391 | 36″ x 39″ x 1 mil |

| 100 |

| IH016 | 36″ x 39″ x 1mil |

| 100 |

Plus II Hot Water Soluble Bags – Extra Heavy Duty for Mops

Dissolves in water above 71°C or 160°F

| P/N | Size | Description | Qty/Case |

| 1120332 | 20″ x 33″ x 1.6 mil |

| 100 |

| 1128392 | 28″ x 39″ x 1.5 mil |

| 50 |

| 1160602 | 60″ x 60″ x 1.5 mil |

| 20 |

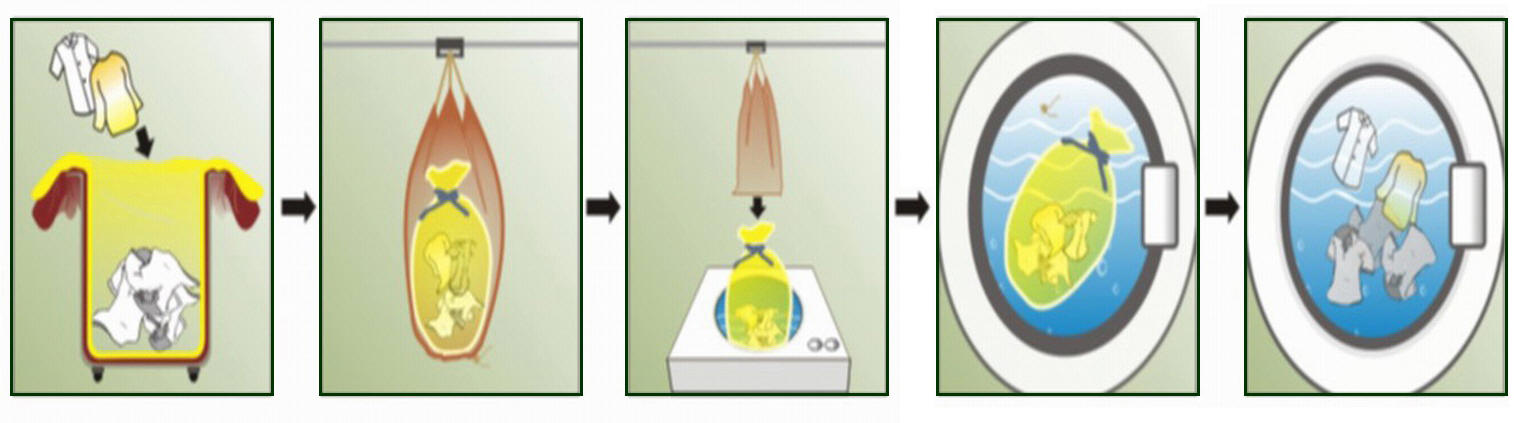

Water Soluble Laundry Bag Operating Instructions

IN STORAGE

1. Keep bags sealed within their protective over-wrap until they are need for use.

2. Once a bag is removed from the pack, keep the remaining bags within the over-wrap material. This gives some measure of protection against accident exposure to moisture.

3. Store over-wrapped water soluble laundry bags at 45°F to 86°F and in Relative Humidity of 20% to 70% for optimum shelf life.

AT SETUP AND IN USE

1. Handle the bags with dry hands only. Avoid any contact by moisture with the bag film to preserve the film’s strength and integrity.

2. IMPORTANT: A linen item known to be dry should be the first item placed in the bag. So it will gravitate to the bottom. It provides a significant measure of protection to the bag in the event moist items are later placed in that bag.

3. Do not place overly wet items in the bag at any time. Remember the bag is sensitive to moisture in any form.

AT CLOSURE

1. Expel as much excess air as possible before closing bag, taking care to avoid expelling air in your face. Reduction of trapped air content makes the closed bag a stronger unit for trans-shipment.

2. A colored neck tie is provided with every bag. Use it close the bag.

3. Caution: Do not knot the bag film as a means of closure. Such knots inhibit solubility during laundering.

4. The closed water soluble laundry bag should be placed within another outer bag for movement within and outside the hospital. This reduces the chance of puncture or snapping en-route to the laundry.

IN THE LAUNDRY:

1. The closed water soluble bag should be placed in the wash wheel or tunnel. Pre-sorting is contraindicated because the soiled linen is assumed to be contaminated.

2. During the initial cold flush cycle, whatever cold water soluble or hot water soluble type, the bag will open and begin to disintegrate, allowing contact with the linen by the wash water.

3. For complete liquefaction of the film we urge the following:

A. Do not overload the washer beyond its rated capacity.

B. Be sure the water temperature reaches at least 149°F during the wash cycle

C. The 149°F water should have been swirling around the bag linens for 40 seconds before the wash chemicals (detergent, alkali, etc.) are injected. Wash at 149°F water for 15 minutes minimum.

**Packing method alternative:

1. All bags are individually folded. Or

2. All bags are on the roll.

All bags are equipped with colored tie.

Caution: These Bags Are Packed in a Polyolefin Oute