Comprehensive range of cleanroom packaging sizes and thicknesses are available in-stock and we can custom fabricate whatever size or gauge you need.

Tubular and Single Wound Roll Stock

Available from 2″ to 58″ width

Bottom Seal Bags

Available from 2″ to 24″ width to 40″ length

Pouches

Available from 2″ to 24″ width to 24″ length

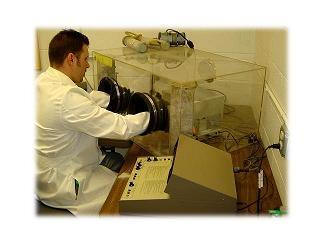

Contamination control is now a major concern for most advanced manufacturing technologies. Every day, skin flakes, dandruff, cotton, dust, tobacco smoke, bacteria, viruses, pollen, fungi spores, formaldehyde, water vapor and other contaminants are carried into your facility by your workers, products and packaging materials. Even your facility can be a source of contamination through its ventilation system, flooring and wall coverings, etc.

Microprocessors are devastated by dust. Pharmaceuticals require absolute standards of cleanliness both in sterile processing and in packaging. Medical, aerospace, photographic, optical, data and food processing, precision bearings, laser production – the list of industries requiring contamination-free production facilities lengthens as technology advances. Our clean room products provide a full spectrum of contamination control services and supplies.

Discover how room cleanliness is equated to air changes/hr. and what cleanliness levels represent. Then contact us discuss your needs. We are committed to providing cost-effective ways to increase productivity and profitability through contamination control.

Our stringent quality control measures, including double- and triple-packaging, ensure the integrity of our product and yours. We have perfected a comprehensive set of standards and guidelines that we scrupulously maintain on each project. For example, every package of our film is manufactured in our own Class 10/100 clean room and sent to you airtight in double- or triple-barrier-sealed overwraps, bearing a Certificate of Conformance to government, NASA Clean Room Products standards.

We are committed to advancing film technology, and providing individualized customer service.

We put a great deal of research has gone into the improvement of film technology. We invite you to put our knowledge and techniques to work for you. Our technical staff will analyze and assist with your requirements. We can help you select the best film product for your needs and we can help design custom machinery and apparatus for you, as well. We welcome your inquiries.

*Liquid particle contour test result available with every order.

Nylon and Anti-Static Nylon

The most effective heat-sealable plastic films for long-term Level I packaging of critical, precision parts. These films create excellent primary barriers for packaging electronics, pharmaceutical products, and precision bearings and components.

Clean Room Products’ NYLON and ANTI-STATIC NYLON are fabricated of Nylon 6, a polyamide. Nylon 6 has the maximum stiffness, strength and heat-resistance of all the nylons, and is therefore the most commonly used nylon for a variety of applications.

It should be noted, however, that all nylons absorb a certain level of water from the atmosphere, and that the equilibrium point of their moisture-absorption depends on the relative humidity.

Features

- Holds up under elevated temperatures

- Superior gas barrier properties

- Extremely oil- and grease-resistant

- Maximum resistance to abrasion, wear and puncture

- Autoclavable and excellent for pharmaceuticals

- NYLON is FDA-approved for packaging food and meat (Anti-static nylon is not FDA-approved)

Cleaned and packaged in our Class 10/100 clean room. (Other government, industry and company specs met on request.) Available in lay-flat tubing, bags and centerfold sheeting in a variety of standard sizes and thicknesse. Custom sizes and gauges also available.

|

Property |

Test Method |

Typical Value |

|

Tensile Strength @ Break |

D638 |

10,000 psi |

|

Elongation @ Break |

D638 |

300% |

|

Tensile Yield Strength |

D638 |

>7000 psi |

|

Water Absorption, 24 hr. |

D570 |

1.3–1.9% |

|

Melting Point |

C177 |

216 C |

|

Flammability |

C177 |

Yes |

|

Surface Resistivity |

— | 1012 |