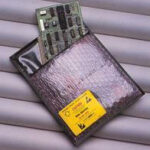

Protect ESD-sensitive products from static and moisture with our Dri-Shield barrier bags. Available in stock sizes or in custom dimensions upon request.

Dri-Shield 2000 Metalized Barrier Bag

By becoming the first to meet the requirements of MIL-B-81705C Type I, the Dri-Shield 2000 Moisture Barrier Bag technology has reset the standard for DRYPACK™.

By becoming the first to meet the requirements of MIL-B-81705C Type I, the Dri-Shield 2000 Moisture Barrier Bag technology has reset the standard for DRYPACK™.

The Dri-Shield 2000 bag replaces costly nylon/foil laminates with metalized polyester and offers the strongest price/performance relationship in the dry packing of moisture sensitive devices.

The Dri-Shield 2000 bag also provides full protection from ESD, static fields and tribocharging.

Features:

- Strong, light weight; suitable for vacuum packaging and nitrogen flushing.

- Meets the electrical and physical requirements of EIA 583, EIA 541, EIA 625 and MIL-B-81705C, Type I.

- Static safe; dissipative inner and outer surfaces.

- Amine free, passes out gassing and corrosion tests.

- Used for packaging SMD’s in trays, shipping tubes, and tape and reel.

- Printed with ESD and moisture warning symbols.

- Date and lot coded for QC traceability.

- Heat Sealable.

- Testable to industry standards.

Structure:

Multiple layers of metalized polyester provides puncture resistance and moisture barrier for this economical dry package. This highly reliable material meets or exceeds the MVTR and EMI/RFI/Static Shielding requirements of MIL-B-81705C, Type I and EIA 583, Type I for static safe, moisture barrier packaging.

Order Number:SC2000-700(W”xL”)

Dri-Shield 2700 Metalized Barrier Bag

With almost twice the puncture resistance of the Dri-Shield 2000, the Dri-Shield 2700 Moisture barrier Bag provides superior drop test performance, and rivals foil laminates for low Moisture Vapor Transmission Rate (MVTR).

With almost twice the puncture resistance of the Dri-Shield 2000, the Dri-Shield 2700 Moisture barrier Bag provides superior drop test performance, and rivals foil laminates for low Moisture Vapor Transmission Rate (MVTR).

The Dri-Shield 2700 is made with the same price/performance technology as the Dri-Shield 2000. With a huge 35 pound puncture resistance, the Dri-Shield 2700 bag is the perfect choice for packaging tubes, trays and reels that have troublesome sharp edges, eliminating expensive end plugs and foam caps. For DRYPACK™, the Dri-Shield 2700 moisture barrier bag is the cost effective, premium performance product.

The Dri-Shield 2700 bag also provides full protection from ESD, static fields and tribocharging.

Features:

- Excellent moisture barrier.

- Maximum puncture resistance. Withstands the harshest vacuum packaging applications.

- Meets the electrical and physical requirements of EIA 583, EIA 541, EIA 625 and MIL-B-81705C, Type I

- Static safe: dissipative inner and outer surfaces.

- Amine free, passes outgassing and corrosion tests.

- Used for packaging SMD’s in trays, shipping tubes and tape and reel.

- Printed with ESD and moisture warning symbols.

- Date and lot coded for QC traceability.

- Heat sealable.

- Testable to industry standards.

- Dri-Shield 2700 Specifications.

Order Number:SC2700(W”xL”)

Dri-Shield 3000 Nylon/Foil Barrier Bag

When you want a foil barrier bag for your DRYPACK™ requirements, the Dri-Shield 3000 offers the best price/performance combination.

When you want a foil barrier bag for your DRYPACK™ requirements, the Dri-Shield 3000 offers the best price/performance combination.

The Dri-Shield 3000 Moisture Barrier Bag, made of static dissipative nylon, aluminum foil, and static dissipative polyethylene, has an extremely low MVTR and provides excellent moisture protection for Surface Mount Devices.

The Dri-Shield 3000 bag also provides full protection from ESD, static fields and tribocharging.

Features:

- Excellent moisture barrier.

- Suitable for vacuum packaging and nitrogen flushing.

- Meets the electrical and physical requirements of EIA 583, EIA 541, EIA 625 and MIL-B-81705C, Type I.

- Static safe: dissipative inner and outer surfaces.

- Amine free, passes outgassing and corrosion tests.

- Used for packaging SMD’s in trays, shipping tubes and tape and reel.

- Printed with ESD and moisture warning symbols.

- Date and lot coded for QC traceability.

- Heat Sealable.

- Testable to industry standards.

- Dri-Shield 3000 Specifications.

Order Number: SC3000(W”xL”)

MPK-8800 Moisture Barrier Static Shield Bag

Extra Packaging’s MPK-8800 High Puncture Foil Moisture Barrier Bags are made of multiple layers of Polyester, Nylon, Foil and Polyethylene to provide a strong, safe package for your ESD and moisture sensitive products. This highly flexible structure is easy to vacuum and seal. The foil layer assures compliance with the Moisture Vapor Transmission Rating (MVTR) required by the IPC/JEDEC J-STD-033 specification for the handling, packaging and shipping of moisture-sensitive surface mount devices. The multi-layer construction provides superior puncture resistance against vacuum packaged trays, reels and tubes. Extra Packaging bags are coded for QC traceability.

Extra Packaging’s MPK-8800 High Puncture Foil Moisture Barrier Bags are made of multiple layers of Polyester, Nylon, Foil and Polyethylene to provide a strong, safe package for your ESD and moisture sensitive products. This highly flexible structure is easy to vacuum and seal. The foil layer assures compliance with the Moisture Vapor Transmission Rating (MVTR) required by the IPC/JEDEC J-STD-033 specification for the handling, packaging and shipping of moisture-sensitive surface mount devices. The multi-layer construction provides superior puncture resistance against vacuum packaged trays, reels and tubes. Extra Packaging bags are coded for QC traceability.

Features:

- Meets electrical and physical requirements of IPC/JEDEC J-STD-033, MIL-PRF-81705 Type 1, EIA 583, EIA 541, EIA 625, and EOS/ESD Standards.

- Foil Moisture Barrier Bag

- Static Shield

- Abrasion Resistant

- 5 mils of polyester, nylon, foil and polyethylene provide high puncture resistance and a low moisture vapor transmission rate (MVTR). This heavy-duty foil barrier meets or exceed the moisture and ESD protective requirements of IPC/JEDEC J-STD-033, MIL-PRF-81705 Type 1 and EIA 583 for packaging static and moisture sensitive electronics devices.

Order Number: MPK-8800(W”xL”)