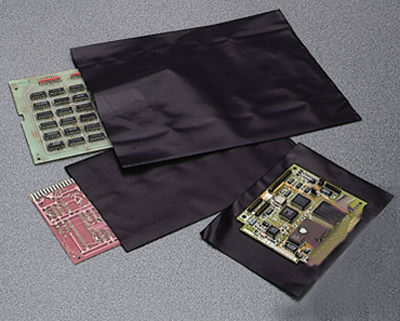

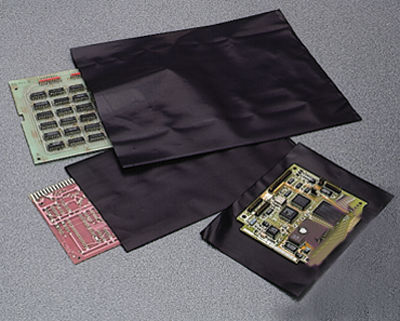

Our black conductive film meets electrical requirements of MIL-P-82646A. It is made from a single layer of carbon-loaded polyethylene and its conductivity does not depend on humidity. It is non-sloughing, does not contaminate components it comes in contact with despite repeated use, and is groundable.

Properties:

- Color – Black Opaque – Printable

- Tensile Strength – >2000 PSI

- ASTM D 882

- Elongation (MD %) – >150%

- ASTM D 882

- Dart Impact – 250 to 700 grams

- ASTM D 1709

- Tearing Strength – >400 lbs. per inch

- ASTM D 882

- Burst (Mullen) – 20 to 60 PSI

- ASTM D 774

Performance:

- Volume Resistivity – <30,000 OHMS/cm

- Surface Resistivity – <30,000 OHMS/Sq

- Meets ASTM D 991, ASTM D 257 and is ROHS Compliant

Product is suitable for automatic bag-making machines:

- Temperature – 250°F – 375°F

- Time – 0.5 – 3.5 seconds

- Pressure – 30 – 70 PSI

Applications:

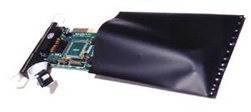

- For packaging of static sensitive components, where

electrostatic contamination is a problem.

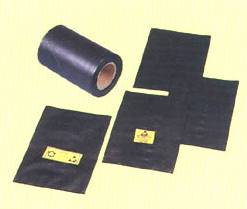

Products Available:

- Bags

- Tubing

- Sheeting

Black Conductive – MIL-P-82646

Extra Packaging is U.S. Navy certified for Black Conductive film and bags to MIL-P-82646. Black Conductive bags and film must be a run at .0035/.004 mils to conform to the MIL Specification. However, we can extrude down to .002/.0025 upon request.

Production Style Available:

Bags:

- Bottom Seal

- Side Weld

- Zipper

- Compartment

- Custom

- Gauge Range: .002 to .010 mil

Film:

- Tubing

- Centerfold

- Single Wound Sheeting

- Double Wound Sheeting

- J Film

- U Film

- 2″ – 60″ Layflat

Materials: Conductive Carbon PE Materials

Application: Highly recommended for packaging of explosive powders and other critical applications. The material has low electrical resistance, and allows electrons to flow easily